Welcome To

SHINE Glass

Welcome to SHINE Glass in China: Shandong highest rated and most trusted glass factory. Your top choice for residential & commercial glass.

Laminated Glass for Canopy

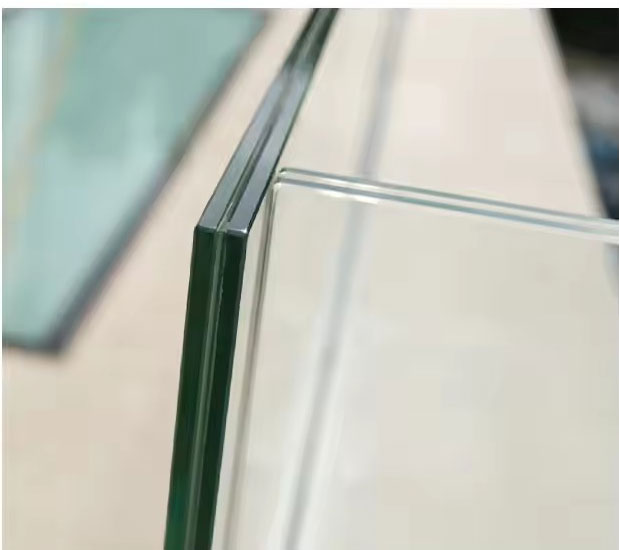

- Laminated glass is two or more sheets of glass permanently bonded together with one or more PVB interlayers using heat and pressure. The glass and interlayers are available in a variety of colors and thicknesses which provide the desired appearance and performance to meet the relevant building code standards and customer requirements.

Description

Product Specification

- ProductLaminated Glass

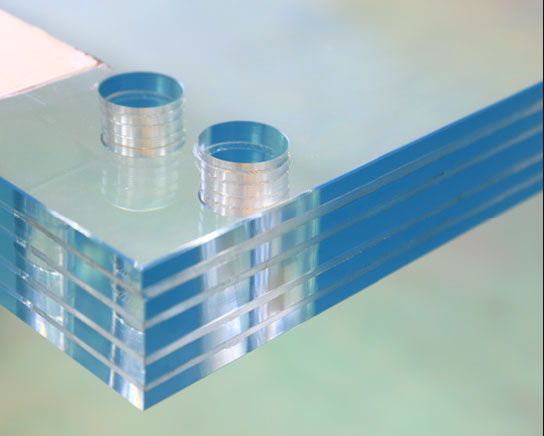

- Glass thickness3mm+3mm; 4mm+4mm; 5mm+5mm; 6mm+6mm; 8mm+8mm; 10mm+10mm; 12mm+12mm; 15mm+15mm; 19mm+19mm (Customizable)

- Glass typesClear glass, ultra-clear glass, tinted glass, patterned glass, frosted glass, etc.

- SizeAs per customer requirements, Max raw glass size 4600mm*9000mm and 3300mm*16000mm Interlayer: SGP/ PVB/ EVA

- ColorClear/ Ultra Clear/ Tinted/ Coated Color

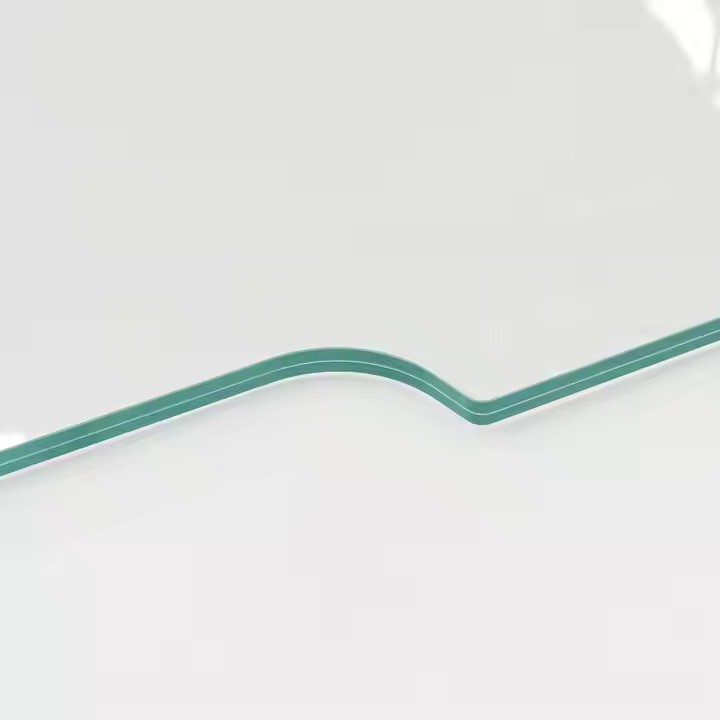

- Optional ProcessingCutting to size, Edging, Drilling holes, Side opening, Tempering, Coating, Printing

- Packing OptionsCE, BS, SGCC, SAI, CCC

- MOQ100 square meters

PRODUCT DETAILS

What are the benefits of laminated glass?

-

Safety and reduced risk of injury

Under sufficient impact force, laminated glass will break. Glass fragments tend to adhere to the plastic interlayer and remain largely intact, reducing the risk of injury. This is particularly important when there is a risk of broken glass falling from high-rise buildings, or from overhead applications such as roof glazing, canopies and skylights. In hurricane-resistant applications, the glass can help prevent water and air from entering the building.

-

Control of noise pollution

Acoustic laminated glass adds noise reduction to other benefits of laminated glass, helping to reduce noise levels so that people can be more comfortable in their living and work spaces.

Specifically designed acoustic interlayers reduce vibrations and significantly improve the sound insulation compared to float glass or even standard laminated glass. -

Solution for your security concerns

Heat strengthened and tempered glass can be incorporated into laminated glass units to further strengthen the impact resistance. This type of laminated glass is often specified for applications where anti-intrusion or forced-entry security are concerns, ballistic and blast mitigation, and hail protection.

-

UV protection properties

When architects require plenty of natural daylight to enter a building without damaging interior furnishings and fittings – laminated glass can absorb up to 99% of the damaging UV rays which can be responsible for up to 50% of fading This protection means that interior surfaces and furniture are likely to last longer.

Products Application

-

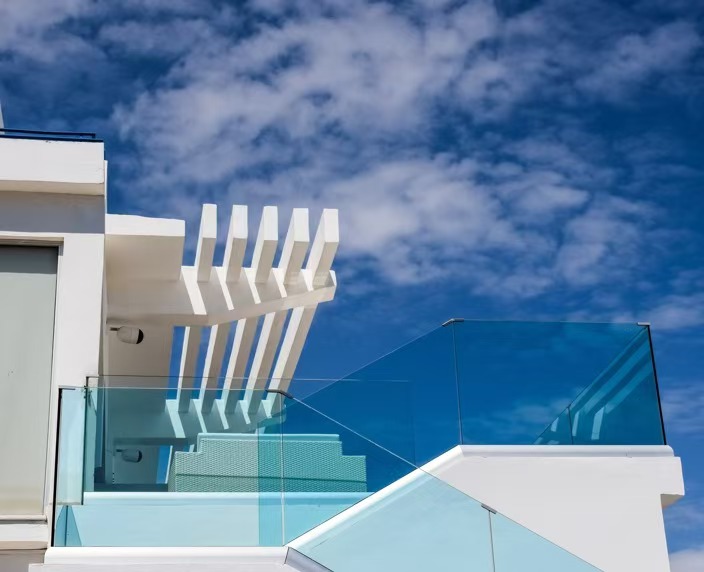

Railing Glass

6+0.76PVB+6mm Drak Blue Laminated Glass

3+0.38PVB+3mm Clear Laminated Glass -

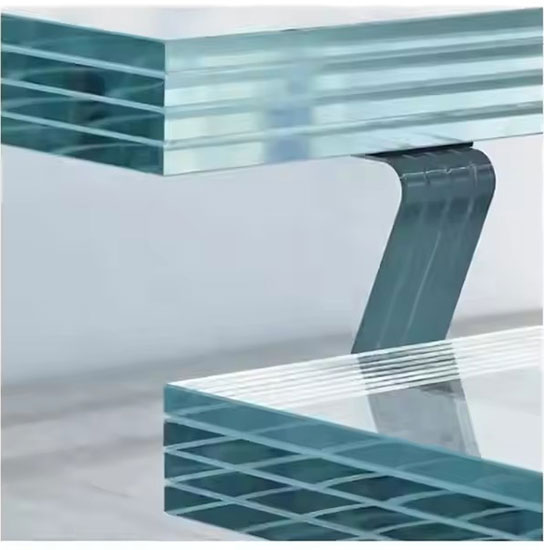

Stair Guardrail and Walk On Glass

10+1.52PVB+10mm Laminated Glass

8+1.14PVB+8+1.14PVB+8mm Laminated Glass -

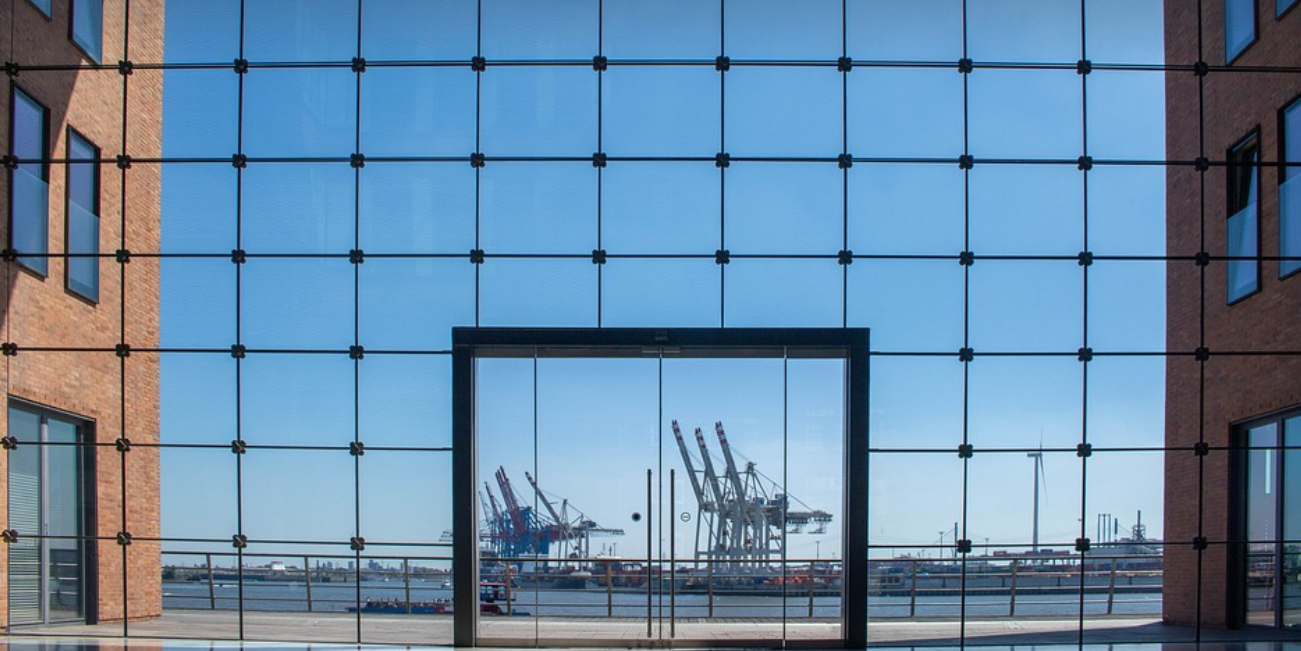

Curtain Wall Glass

6+1.14PVB+6mm Laminated Glass

8+1.52PVB+8mm Laminated Glass -

Glass Roof & Skylight

6+0.76PVB+6mm Laminated Glass

5+0.76PVB+5mm Laminated Glass

SHINE LAMINATED GLASS PRODUCTION LINES

We will provide you with the best quality and service

Packing&Shipping

2.Before packing, we will inspect each glass sheet. because we will make good quality products.

3.Using brand new, durable, seaworthy plywood crates with foam protection inside.

4.Each crate will be fasten by metal belt.

EN

EN  中文

中文